By Florengen Arvin Parulan (Automotive Researcher)

As modern vehicles transition from mechanical machines to intelligent, connected systems, the backbone of these innovations lies in robust in-vehicle networks. The Resistant Automotive Miniature Network (RAMN) is a cutting-edge solution designed to guarantee reliable communication among every electronic control unit (ECU), sensor, and digital component — even under extreme conditions. However, experimenting with a full-scale RAMN setup might be cost-prohibitive or overly complex for early-stage development. That’s where replicating RAMN on a single STM32 board becomes an invaluable, hands-on approach to learning and prototyping.

In this blog post, we’ll walk you through the process of creating a simplified yet powerful proof of concept that mimics the essential functions of RAMN using an affordable and versatile STM32 board. Whether you’re an automotive engineer, a hobbyist, or someone who’s just curious about advanced networking in automotive applications, this guide will help you understand how to leverage the STM32 platform to replicate key features of RAMN.

Furthermore, by using only one STM32 board, our research remains consistent and focused. With this single, reliable platform, any success or challenge is directly tied to our concept rather than hardware variations. This streamlined approach simplifies troubleshooting, optimizes development, and establishes a solid foundation for scalable, repeatable results before broader implementation.

RAMN and its importance

RAMN is specifically engineered for automotive environments. It guarantees seamless communication among every ECU, sensor, and digital component within a vehicle. In contrast to traditional wiring harnesses, which are often prone to errors and signal loss, RAMN replaces bulky connections with a sleek, modular design. This innovative architecture is built to endure harsh conditions, including extreme temperatures, high vibrations, and constant electromagnetic interference, ensuring both reliable performance and improved cybersecurity.

Why use a single STM32 board?

Using a single STM32 board to replicate advanced automotive networks such as RAMN offers a practical and accessible approach for prototyping and experimentation. Here are some compelling reasons:

- Cost-effective prototyping: STM32 boards are compact, affordable, and widely available, making them an attractive option for early-stage development without the high expense of full-scale systems.

- Integrated peripherals: With built-in features like CAN interfaces and multiple serial communication options (e.g., UART, SPI, I2C), the STM32 platform can efficiently simulate various network nodes and communications, closely mimicking a complete RAMN setup.

- Rapid development: The robust ecosystem around STM32 — including tools like STM32CubeIDE, extensive libraries, and community support — streamlines the development process. This allows for quick testing, debugging, and iteration of designs.

- Flexibility for experimentation: A single STM32 board provides a manageable environment to explore key concepts of in-vehicle networking, such as data routing, error handling, and secure communication protocols, paving the way for further scaling and refinement in future projects.

By leveraging a single STM32 board, engineers, hobbyists, and developers can gain valuable insights into the fundamental principles of automotive communication networks and build a practical foundation for more complex, automotive-grade implementations in the future.

Overview of the RAMN board

Before diving into the replication process, it’s essential to understand what sets RAMN apart:

- Seamless communication: RAMN connects all ECUs, sensors, and digital modules securely, ensuring uninterrupted data exchange.

- Environmental resilience: Built primarily from automotive-grade components (capable of operating from -40 to 150°C), RAMN handles physical stresses that typical development boards cannot.

- Modularity and scalability: Its architecture replaces traditional bulky wiring with a streamlined, modular solution, leading to shorter communication pathways, improved signal integrity, and greater overall reliability.

- Security focus: With advanced encryption and secure protocols, RAMN protects data integrity against the rising tide of cybersecurity threats in modern vehicles.

Setting up the STM32 prototype environment

What you’ll need

- STM32 board: STM32L552ZE.

- Development environment: Install STM32CubeProgrammer, STM32CubeIDE.

- Peripheral hardware: Basic jumper wires, breadboards, a TJA1050 CAN bus transceiver, and CANable120R.

- Documentation: Have the STM32 reference manuals and datasheets handy for detailed peripheral configuration.

Configuring the hardware

- Board setup: Mount your STM32 board, connect any additional peripherals (like a CAN transceiver module), and ensure proper power supply through USB connection.Pin assignments:

- FDCAN1_TX(PB9) to TX pin of TJA1050 CAN bus transceiver

- FDCAN1_RX(PB8) to TX pin of TJA1050 CAN bus transceiver

- CANH of TJA1050 CAN bus transceiver to CANH of CANable

- CANL of TJA1050 CAN bus transceiver to CANL of CANable

- Connect all 5Vs and GND respectively.

- Software installation: Install STM32CubeIDE and STM32CubeProgrammer for CAN communication.

Step-by-step guide to replicating RAMN

Step 1: STM32CubeIDE

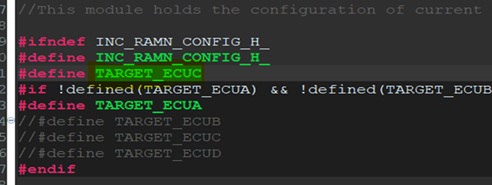

- Configure target ECU in RAMN_CONFIG.H.

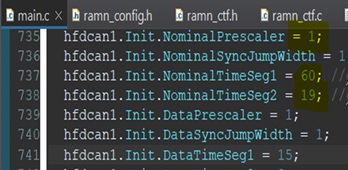

- Set correct baud rate and prescaler in Main.c as shown.

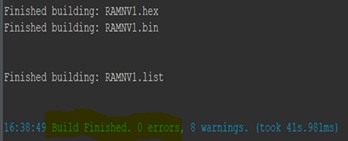

- Build by going to Project and Clean (ELF file to be used later).

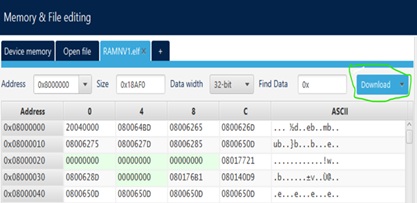

Step 2: STM32CubeProgrammer

- Connect and erase as shown.

- Find and open .Elf file generated in step 1 and typically located at xxxx/RAMN-develop\firmware\RAMNV1\Debug.

- Flash to hardware by clicking Download.

- Disconnect STM32CubeProgrammer.

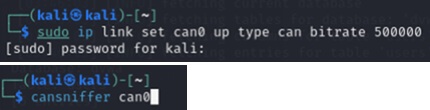

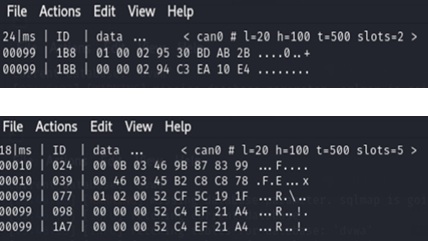

Step 3: Kali Linux

- Set exact baud rate and enter command cansniffer can0.

- ... and RAMN is working

(Note: Press RESET button after each change of ECU.)

Advantages and limitations of the single-board approach

Advantages

- Cost-efficiency: A single STM32 board offers a low-cost entry point for understanding and prototyping RAMN-like networks.

- Simplicity: The setup is straightforward and can be assembled quickly, ideal for early-stage development and experimentation.

- Flexibility: Virtualizing nodes on one board provides an adaptable platform for testing various communication scenarios and network configurations.

Limitations

- Scalability: Although you can simulate nodes, this approach does not fully replicate the distributed processing and physical resilience of a true multiboard RAMN system.

- Automotive-grade performance: The STM32 board might not completely match the environmental robustness of automotive-grade components found in full-scale RAMN implementations.

- CAN bus termination: A single-board setup might have limitations in accurately replicating the complete CAN/CAN-FD bus behavior as observed in real vehicles.

Conclusion

Replicating RAMN using a single STM32 board is an excellent way to dive into advanced automotive networking concepts without a full investment in complex hardware setups. This approach not only provides valuable insights into data routing, error management, and secure communications, but also lays the foundation for further exploration into automotive-grade designs.

By balancing cost, open-source development, and fidelity to real ECU networks, this STM32-based prototype can help bridge the gap between theoretical design and practical application. Whether you plan to develop sophisticated ECUs or simply want to understand the inner workings of modern vehicle networks, this project is a good starting point.

Moreover, our project demonstrates that a single STM32 board is more than just a proof-of-concept tool — it’s a versatile platform capable of powering dynamic applications like capture-the-flag challenges. Its consistent performance and reliability pave the way for innovative, engaging solutions.